TARDIGRADE

ERAC 925

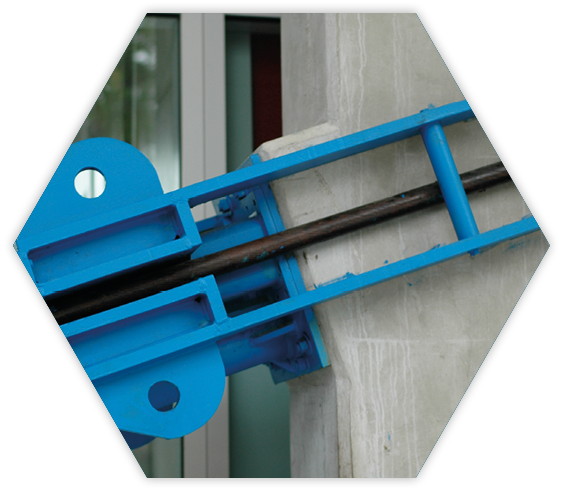

TWO COMPONENT, SOLVENT FREE, EPOXY RESIN BASED, THIXOTROPIC ANCHORING AND ADHESIVE MORTAR

Tardigrade ERAC 925, is a two component, solvent free, epoxy resin based, paste consistency anchoring mortar and adhesive mortar.

FIELDS OF APPLICATION

- On concrete, natural stone, brick, wood, steel and metal surfaces

- During fertilization applications

- Staircase scare, fixation of fence and stub elements

- When the door and window frames are fixed

- Gluing materials such as ceramics, tiles and granites to the surface

It is used as anchorage, assembly, and adhesive mortar

ADVANTAGES

- Easy application

- May applied without primer

- Solvent free

- Excellent adhesion

- Non-sag on vertical applications

- High loading capacity

- High resistance against mechanical and chemicals

- Durable against thermal shocks

APPEARANCE

Part A (Epoxy Resin) : Paste – Gray

Part B (Epoxy Hardener) : Paste – Cream

PACKAGING

- Part A: 18 kg. net – Part B: 12 kg. net

- Total Set: 30 kg. net – Total Set: 32,55 kg. gross

- Part A: 4,80 kg. net – Part B: 3,20 kg. net

- Total Set: 8 kg. net – Total Set: 8,90 kg. gross

STORAGE

Store in original sealed containers in dry environment at temperatures between +10⁰C and +30⁰C. Do not put excessive loads on top of the products, which would damage the packaging.

SHELF LIFE

12 months from date of production if stored in original unopened containers. Once opened, product should be consumed within one week as it is stored under appropriate storage conditions.

CHEMICAL STRUCTURE

Part A: Epoxy Resin Part B: Epoxy Hardener

TECHNICAL SPECIFICATIONS

All technical values were calculated based on +23⁰C and 50% relative humidity. Temperature and humidity changes would change technical values.

|