CASTING RESINS

CRYSTAL-TRANSPARENT

RESIN SOLUTIONS

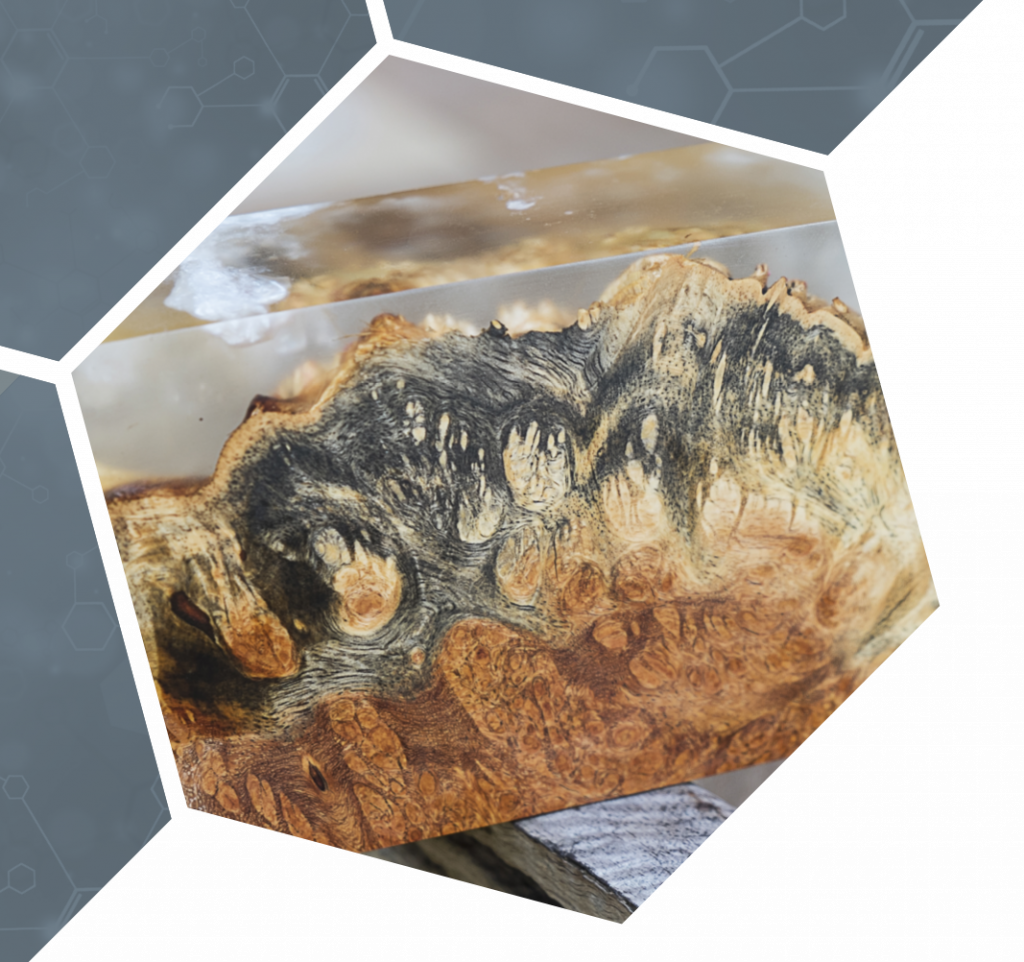

When exceptional clarity and results are needed, Tardigrade’s clear casting resins:

- Have a refractive index similar to glass

- Are compatible with modeling and molding applications

- Produce stunning effects for decorative objects

- Provide advanced technology features

- Are non-allergenic

- And have low VOCs

Industry demands fast curing resins with enhanced mechanical properties such as volume, mass thermal conductivity and waterproofing. Tardigrade’s next-generation chemistry culture line of fast curing resins can be used for casting, filling, cutting, molding, mold compaction and are compatible to be used in conjunction with their hard-working epoxy, polyurethane, polyurea and polyaspartic resin systems.

Additionally, each system can also be formulated to provide UV protection while allowing manufactures the ability to produce long-lasting products designed for use in outdoor spaces.

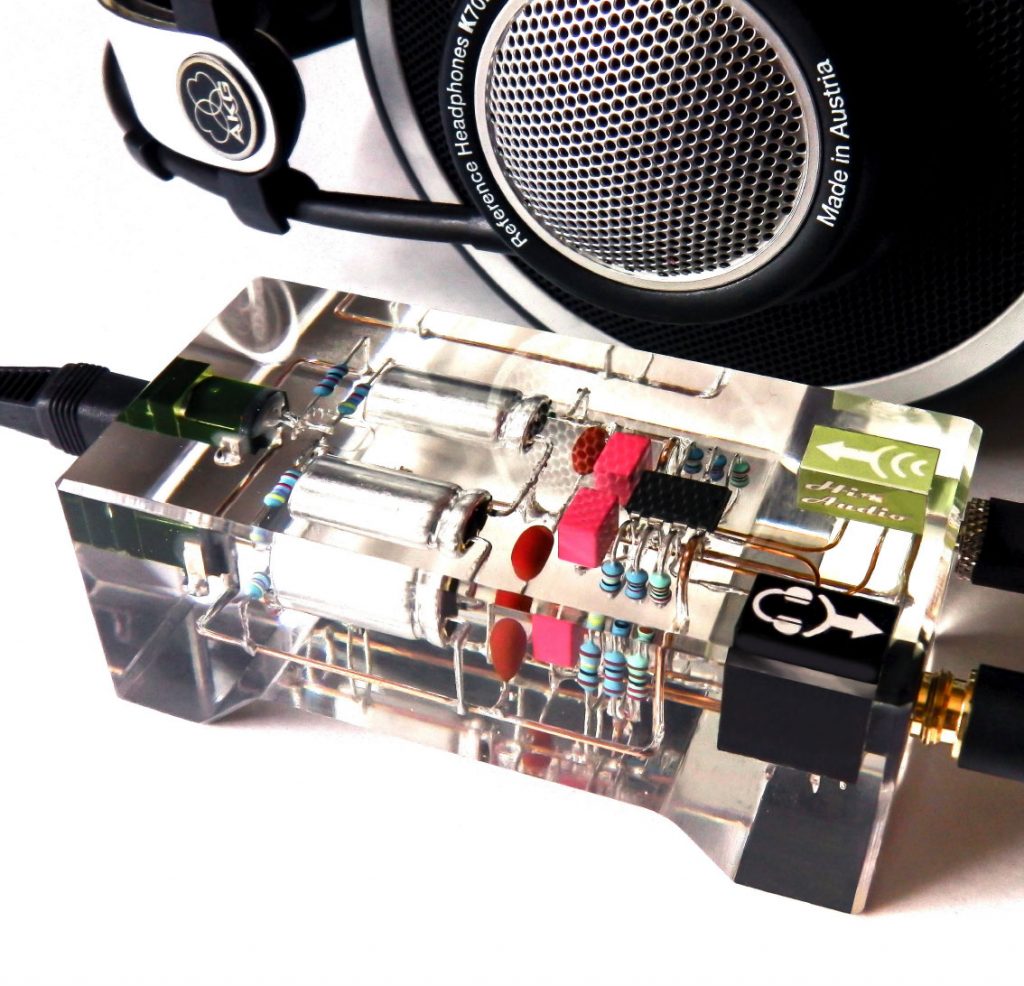

EPOXY CASTING RESINS

Casting materials created with epoxy resins system are more user friendly and less toxic while providing sufficient flexibility and durability compared to low performance resin systems.

POLİÜRETAN DÖKÜM REÇİNELERİ

Casting materials created with polyurethane resin systems offer very good impact resistance and can be designed with exceptional flexibility when needed. Compared to other low performance resin systems, Tardigrade’s polyurethane casting resins are fast curing (surface drying) with a non-offensive odor, feature excellent thermal stability and low heat resistance, making them a stand out product solutions.

Unlike other thermoplastics, our two-component, solvent-free curing/solidifying resin feature a thermoset structure that does not produce a cross-linking chemical reaction during final production.

Typical uses of casting resins:

- Casting and manufacturing of electrical components (transformers, insulators, capacitors, semiconductors, assemblies)

- Covering open contact points (underground cable branches such as arms, energy and telephone lines) for cables and wires

- Melting pot components

- Rapid prototyping

- Building and Monument restoration

- Manufacturing of casting molds

- Model creation (streams, rivers, lakes, replicas, etc.)

- Scratch and weatherproof surface protection by creating cold glaze

- The creation of glaze-like surfaces for colored or colorless crafts

Depending on the application, the following final properties usually express the general character of cured casting resin:

- Mechanical properties such as strength, elasticity, hardness, fracture toughness

- Thermal or thermo-mechanical properties such as expansion coefficient, heat resistance, thermal conductivity, glassy transition temperature

- Electrical properties such as dielectric strength, waterproofing resistance, permeability, monitoring resistance

- Viscosity: If the body or shape to be poured has small gaps or openings, perfect bubble-free casting is only possible when the viscosity is low enough

- Reactivity: The reaction rate of the cross-linking reaction determines the CAP life and viscosity which is directly dependent on the curing time

- Protection: Casting resin is used for electrical waterproofing, dirt and moisture protection in transformers and high voltage windings