TARDIGRADE

PCAP 730

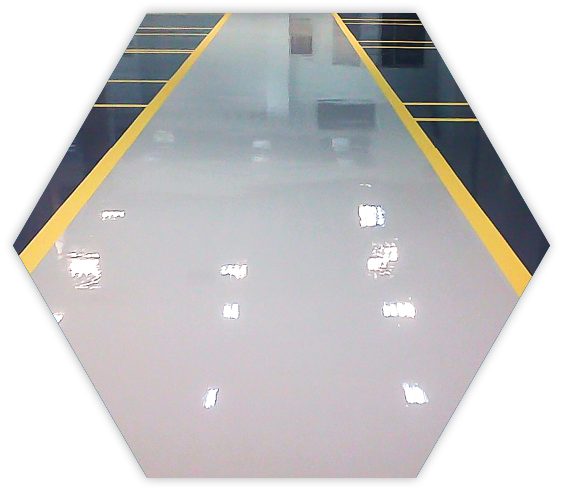

TWO COMPONENT, SOLVENT BASED, SEMI GLOSSY, SELF LEVELING, ALIPHATIC POLYURETHANE TOP COATING

Tardigrade PCAP 730, is a two component solvent base, low viscosity, self leveling, aliphatic polyurethane based, UV resistant, and painting and topcoat featuring semi glossy (semi matte) surface appearance.

FIELDS OF APPLICATION

- Internal and external substrates

- On concrete and cement based mineral surfaces

- In smooth or sand broadcast surface applications

- A high level of hygiene required fields such as hospitals, laboratories and clean rooms

- Kindergartens and care homes

- For outdoor and indoor swimming pools

Used as a semi-gloss (semi-matte) top coat paint and coating material.

ADVANTAGES

- Low viscosity

- Ultrahigh bond strength

- Because of low VOC content, it is an environmentally friendly product

- Ultrahigh penetrating ability

- It has a hard elastic structure

- It is easy to apply, clean and maintain

- High UV resistance with its aliphatic feature

- Glossy appearance

- Hygienic and anti-bacterial

- Resistant to mechanical loads, abrasion and chemicals

APPEARANCE

Mix (Part A +Part B): Transparent / Ral colors

PACKAGING

- Part A: 21 kg. net – Part B: 4 kg. net

- Total Set: 25 kg. net – Total Set: 27,55 kg. gross

- Part A: 4,20 kg. net – Part B: 0,80 kg. net

- Total Set: 5 kg. net – Total Set: 5,90 kg. gross

STORAGE

Store in original sealed containers in dry environment at temperatures between +10⁰C and +30⁰C. Do not put excessive loads on top of the products, which would damage the packaging.

SHELF LIFE

12 months from date of production if stored in original unopened containers. Once opened, product should be consumed within one week as it is stored under appropriate storage conditions.

CHEMICAL STRUCTURE

Part A: Polyurethane Resin

Part B: Polyurethane Hardener (Aliphatic Isocyanate)

TECHNICAL SPECIFICATIONS

All technical values were calculated based on +23⁰C and 50% relative humidity. Temperature and humidity changes would change technical values.

|