TARDIGRADE

PRGF 900

TWO COMPONENT, SOLVENT FREE, POLYURETHANE – POLYUREA HYBRID BASED FILLING MORTAR

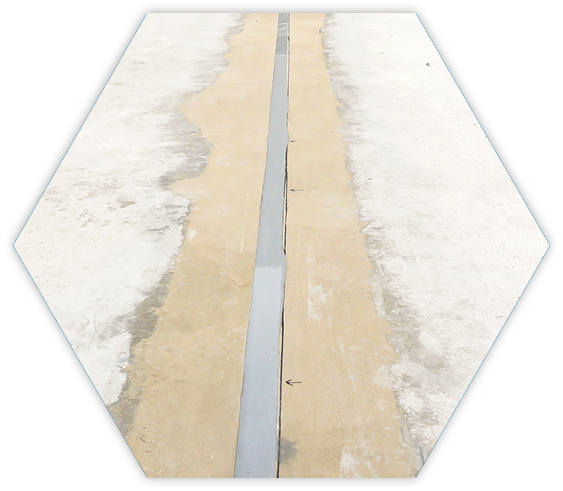

Tardigrade PRGF 900 is two component, solvent free, polyurethane – polyurea hybrid based, cold applied structural filling mortar.

FIELDS OF APPLICATION

- Industrial floors, on cracks occurred in asphalt and concrete roads

- Parking lots, highways, joint repairs and airport concrete runway, where high resistance to oil and fuel is important

- Connection joints of aboveground oil storage and loading ramps

- Connection joints of concrete materials

- Joints on industrial floors

- It is used as a filling and repair mortar.

ADVANTAGES

- Solvent free

- Easy application

- Resistant to thermal shocks

- High bond strength

- High mechanical and chemical resistance, especially against jet fuel and industrial oils

APPEARANCE

Part A (Epoxy Resin) : Liquid – Gray

Part B (Hardener) : Liquid – Yellow

PACKAGING

- Part A: 25 kg. net – Part B: 25 kg. net

- Total Set: 50 kg. net – Total Set: 53 kg. gross

- Part A: 0,30 kg. net – Part B: 0,30 kg. net

- Total Set: 0,60 kg. net – Total Set: 0,75 kg. gross

STORAGE

Store in original sealed containers in dry environment at temperatures between +10⁰C and +30⁰C. Do not put excessive loads on top of the products, which would damage the packaging.

SHELF LIFE

Minimum 12 months for part A and 9 months for part B from date of production if stored in original unopened containers. Once opened, product should be consumed within one week as it is stored under appropriate storage conditions.

CHEMICAL STRUCTURE

Part A: Polyurethane – Polyurea Hybrid Resin

Part B: Polyurethane – Polyurea Hybrid Hardener

TECHNICAL SPECIFICATIONS

All technical values were calculated based on +23⁰C and 50% relative humidity. Temperature and humidity changes would change technical values.

|