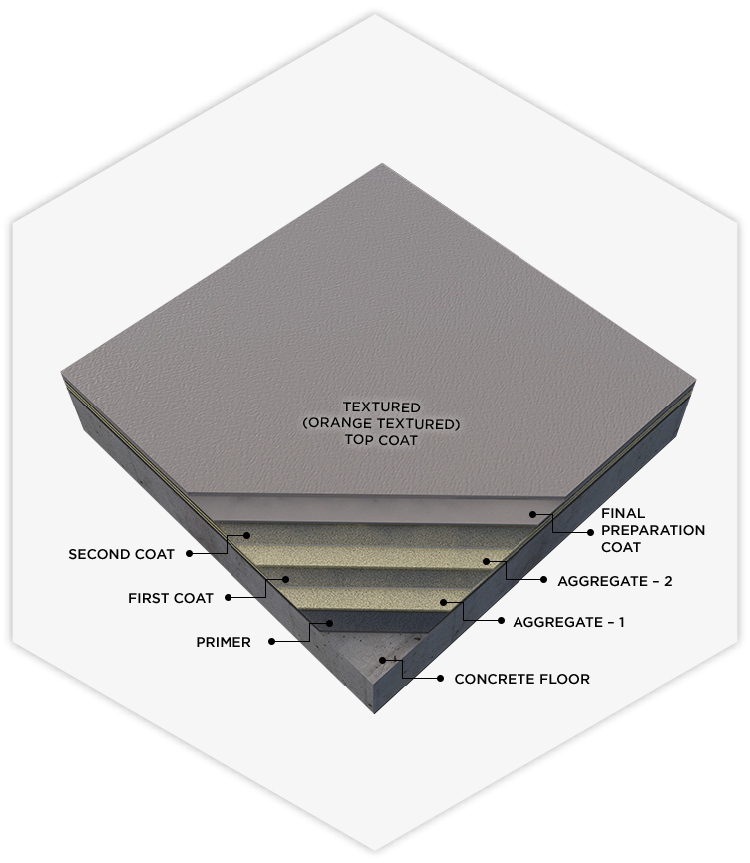

TETC 300

EPOXY TEXTURED (ORANGE TEXTURED) COATING SYSTEM (3,00 mm)

Textured pattern appearance, highly resistant to chemical and physical damages, solvent free, epoxy coating system.

FIELDS OF APPLICATION

- On concrete and cement based mineral surfaces

- Production areas, factories and workshops

- On heavy surfaces such as production areas, workshops, aircraft hangars, automotive industry, loading ramps

- Wet process areas in pharmaceutical and other medical or laboratory buildings

- Control rooms, thermal and hydroelectric power plants

- In fairgrounds, shopping centers and parking lots

used

ADVANTAGES

- Easy application

- Chemical resistance is high

- High mechanical strength

- Wear resistance is high

- It creates a hygienic environment

- Easy to clean

- Has a long coating life

- Compatible with heavy traffic conditions

|

Intended Use |

Product Code |

Coverage (kg/m²) |

|

Primer |

Tardigrade EPST 100 – EPST 110 |

0,300 |

|

Aggregate – 1 |

Tardigrade TGAG 990 (200-500 Micron Aggregate) |

2,000 |

|

First Coat |

Tardigrade EPST 100 – EPST 110 + Tardigrade TGAG 990 (100-300 Micron Aggregate) |

0,350 + 0,350 |

|

Aggregate – 2 |

Tardigrade TGAG 990 (200-500 Micron Aggregate) |

2,000 |

|

Second Coat |

Tardigrade EPST 100 – EPST 110 + Tardigrade TGAG 990 (100-300 Micron Aggregate) |

0,350 + 0,350 |

|

Final Preparation Coat |

Tardigrade ECTX 250 – ECTX 220 |

0,200 |

|

Textured (Orange Textured) Top Coating |

Tardigrade ECTX 250 – ECTX 220 |

0,500 |