TARDIGRADE

PUDM 900

TWO COMPONENT, SOLVENT FREE, POLYURETHANE DILATATION SEALANT MATERIAL

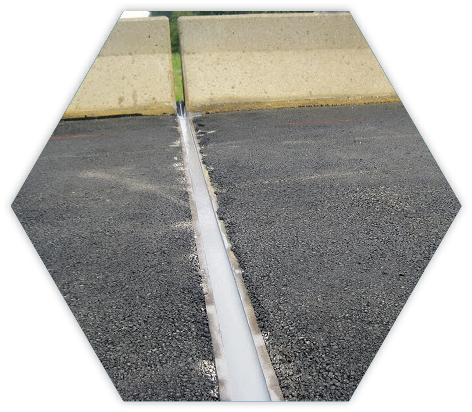

Tardigrade PUDM 900 is a polyurethane based, two component, low viscosity, solvent free, cold applied, reaction cured, flexible and elastic dilatation sealant for wide and narrow horizontal joints.

FIELDS OF APPLICATION

- In wide expansion ranges

- In filling the dilatation joints

- Wide cracks and joint gaps at airports

- In the sealing of the connection elements of open and closed swimming pools

- Corner details of roof, ornamental pool and underground water tanks

- In industrial floor details

It is used as the main filling and dilatation material.

ADVANTAGES

- Flexible and elastic It has crack bridging feature

- Waterproofing feature

- Solvent free

- Compatible with polyurethane systems

- High resistance against abrasion

- Suitable for thick application

- It is safe to use in drinking water storage and distribution channels.

- It is safe to use in drinking water storage and distribution channels

- Easy application

- Maintains its elasticity at low temperatures

- Hygienic and easy to clean

- It provides complete waterproofing and allows walking on its surface

APPEARANCE

Mix (Part A + Part B) : Ral Colors

*Differences in color may occur under influence of direct sunlight. This does not affect the physical and chemical resistance of coating. This does not affect the physical and chemical resistance of coating.

PACKAGING

- Part A: 27 kg. net – Part B: 3 kg. net

- Total Set: 30 kg. net – Total Set: 32,55 kg. gross

- Part A: 5,40 kg. net – Part B: 0,60 kg. net

- Total Set: 6 kg. net – Total Set: 6,90 kg. gross

STORAGE

Store in original sealed containers in dry environment at temperatures between +10⁰C and +30⁰C. Do not put excessive loads on top of the products, which would damage the packaging.

SHELF LIFE

Shelf life is 9 months from date of production if stored in original unopened containers. Once opened, product should be consumed within same day.

CHEMICAL STRUCTURE

Part A: Polyurethane Resin Part B: Polyurethane Hardener

TECHNICAL SPECIFICATIONS

All technical values were calculated based on +23⁰C and 50% relative humidity. Temperature and humidity changes would change technical values.

|