TARDIGRADE

PUWP 395

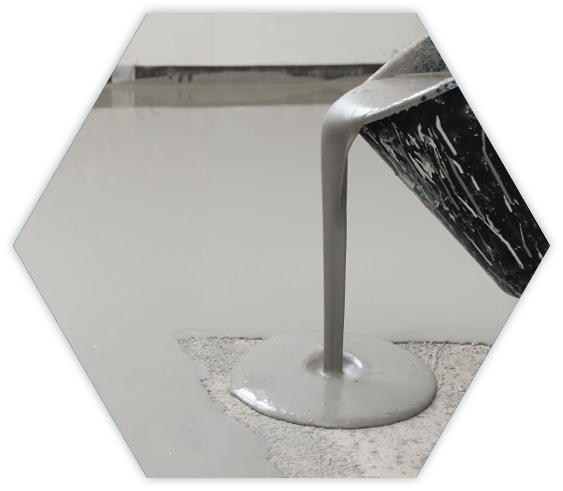

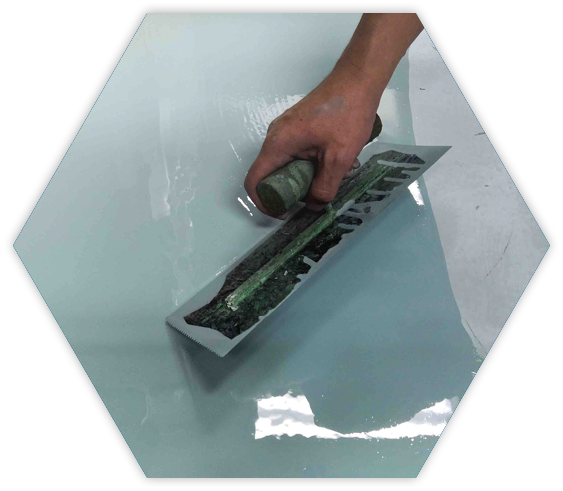

ONE COMPONENT, SOLVENT BASED, POLYURETHANE WATERPROOFING MATERIAL

Tardigrade PUWP 395 is a polyurethane based, one component, low viscosity, solvent based, cold applied, moisture curing, flexible and elastic waterproofing material.

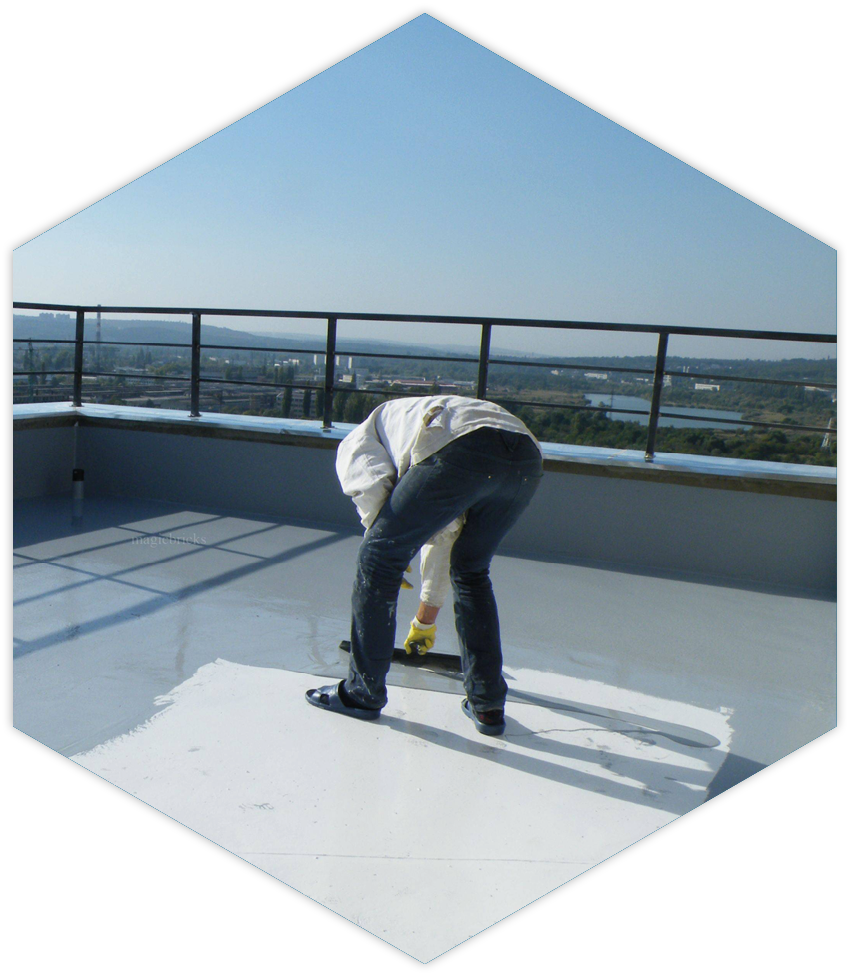

FIELDS OF APPLICATION

- In water tanks, pipes and channels

- Under tile applications of wet floors such as bathrooms and kitchens

- Waterproofing and protection of bridges, tunnels and similar concrete structures

- On roofs, terraces and balconies

- In the insulation of indoor and outdoor swimming pools

- Wet areas in the food, chemical and pharmaceutical industries

- In production, storage and assembly areas

It is used as a waterproofing material

ADVANTAGES

- Flexible and elastic It has crack bridging feature

- High elongation value

- Low viscosity

- High bond strength

- It is safe to use in drinking water storage and distribution channels.

- Easy application

- Can be used in constant contact with water

- Maintains its elasticity at low temperatures

- Hygienic and easy to clean

- Provides complete water and moisture insulation

PACKAGING

-

Net: 25 kg. Gross: 26,00 kg

-

Net: 5 kg. Gross: 5,35 kg

STORAGE

Store in original sealed containers in dry environment at temperatures between +10⁰C and +30⁰C. Do not put excessive loads on top of the products, which would damage the packaging.

SHELF LIFE

Shelf life is 9 months from date of production if stored in original unopened containers. Once opened, the product should be consumed within the same day.

CHEMICAL STRUCTURE

Part A: Polyurethane Resin

TECHNICAL SPECIFICATIONS

All technical values were calculated based on +23⁰C and 50% relative humidity. Temperature and humidity changes would change technical values.

|